How to Test and Replace Motor Carbon Brushes

Carbon brushes are small but critical components in many types of electric motors, especially brushed DC and universal motors. When worn out, they can cause sparking, reduced performance, or even motor failure.

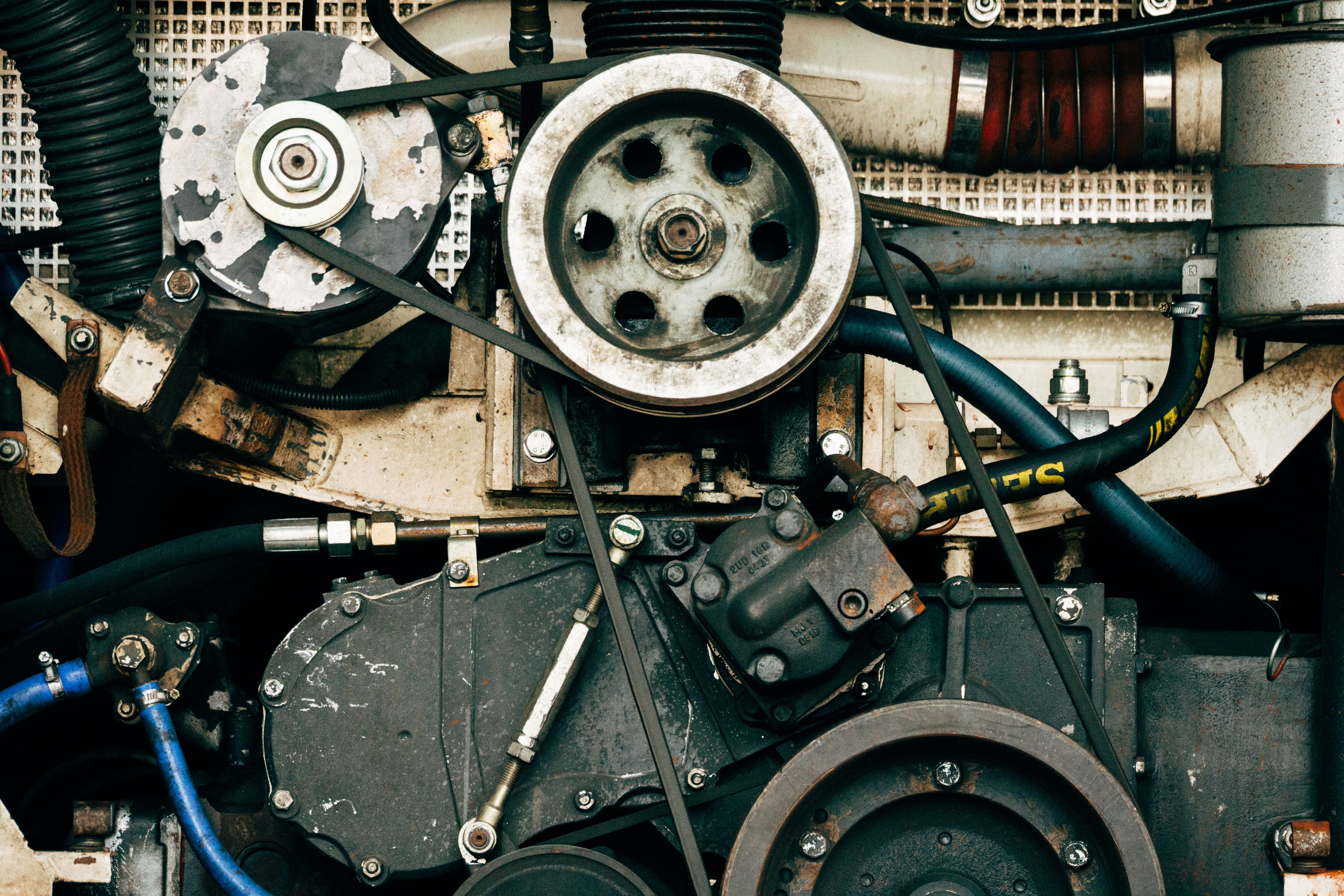

🔍 What Are Carbon Brushes?

Carbon brushes conduct electricity between the stationary and rotating parts of a motor. Over time, they wear down due to friction.

⚠️ Symptoms of Worn Brushes

- Motor doesn’t start

- Excessive sparking at the commutator

- Decreased torque or RPM

- Burning smell or noise

🧪 How to Test Carbon Brushes

- Unplug the motor and open the brush housing.

- Inspect brush length – If it's less than 1/3 of its original size, replace it.

- Use a multimeter to check continuity.

- Check the commutator for wear or damage.

🔧 Replacing Carbon Brushes

- Remove the old brushes gently.

- Clean the brush holder and commutator.

- Insert new brushes of the correct size.

- Reassemble the motor and test operation.

🛠 Maintenance Tips

- Inspect brushes every 3–6 months

- Clean dust from the brush area regularly

- Avoid overloading the motor

- Keep the commutator smooth and polished

✅ Conclusion

Carbon brush maintenance is vital for extending motor life and performance. Regular inspection and timely replacement can prevent expensive failures.